What does an A&P do?

Aircraft mechanics typically do the following:

- Diagnose mechanical or electrical problems

- Repair wings, brakes, electrical systems, and other aircraft components

- Replace defective parts, using hand tools or power tools

- Examine replacement aircraft parts for defects

- Read maintenance manuals to identify repair procedures

- Test aircraft parts with gauges and other diagnostic equipment

- Inspect completed work to ensure that it meets performance standards

- Keep records of maintenance and repair work

Avionics technicians typically do the following:

- Test electronic instruments, using circuit testers, oscilloscopes, and voltmeters

- Interpret flight test data to diagnose malfunctions and performance problems

- Assemble components, such as electrical controls and junction boxes, and install software

- Install instrument panels, using hand tools, power tools, and soldering irons

- Repair or replace malfunctioning components

- Keep records of maintenance and repair work

Airplanes require reliable parts and maintenance in order to fly safely. To keep an airplane in operating condition, aircraft and avionics equipment mechanics and technicians perform scheduled maintenance, make repairs, and complete inspections. They must follow detailed regulations set by the Federal Aviation Administration (FAA) that dictate maintenance schedules for different operations.

Many mechanics are generalists and work on many different types of aircraft, such as jets, piston-driven airplanes, and helicopters. Others specialize in one section, such as the engine, hydraulic system, or electrical system, of a particular type of aircraft. In independent repair shops, mechanics usually inspect and repair many types of aircraft.

The following are examples of types of aircraft and avionics equipment mechanics and technicians:

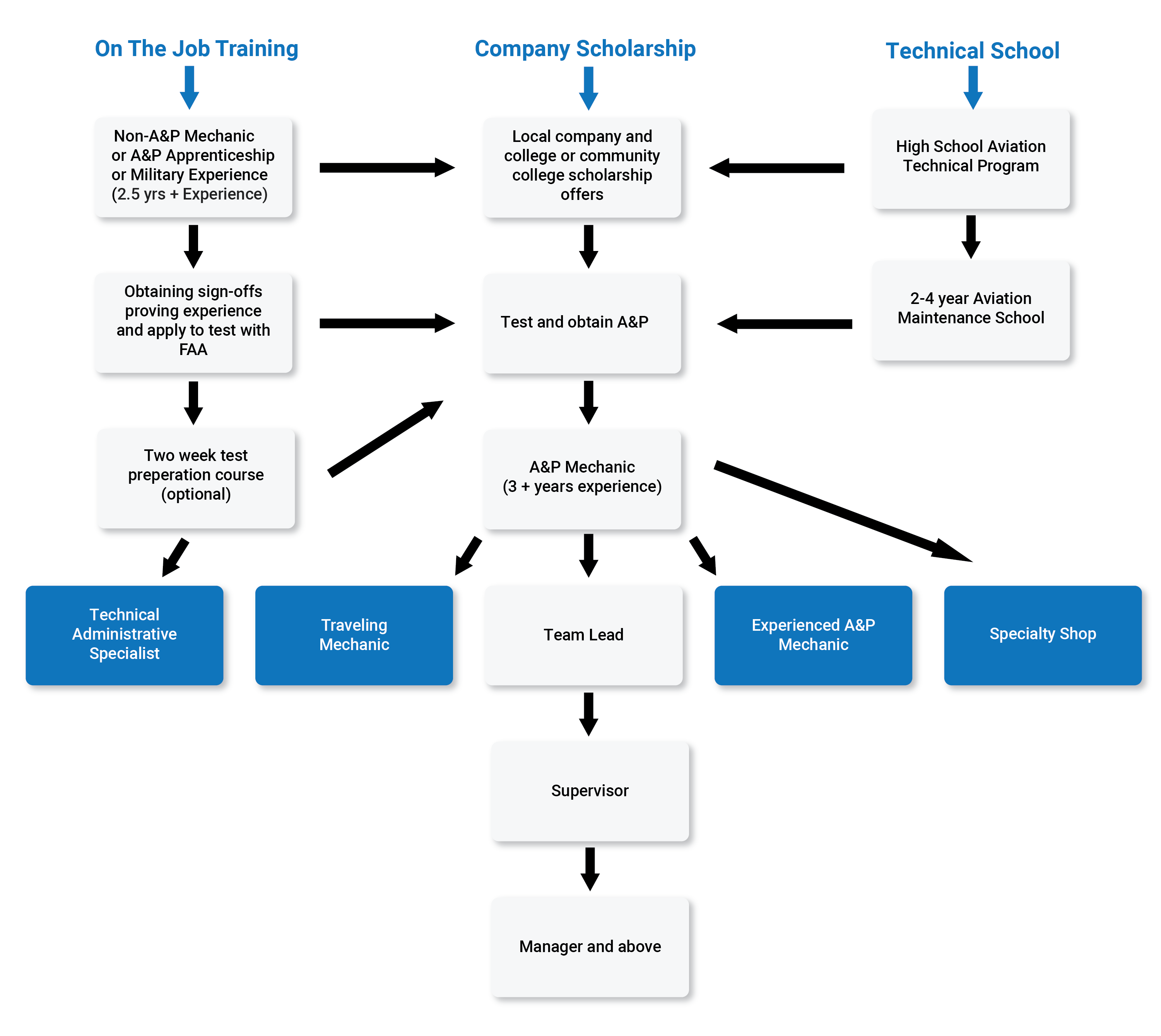

Airframe and Powerplant (A&P) mechanics are certified generalist mechanics who can independently perform many maintenance and alteration tasks on aircraft. A&P mechanics repair and maintain most parts of an aircraft, including the engines, landing gear, brakes, and air-conditioning system. Some specialized activities require additional experience and certification.

Maintenance schedules for aircraft may be based on hours flown, days since the last inspection, trips flown, or a combination of these factors. Maintenance also may need to be done at other times to address specific issues recognized by mechanics or manufacturers.

Mechanics use precision instruments to measure wear and identify defects. They may use x rays or magnetic or ultrasonic inspection equipment to discover cracks that cannot be seen on a plane’s exterior. They check for corrosion, distortion, and cracks in the aircraft’s main body, wings, and tail. They then repair the metal, fabric, wood, or composite materials that make up the airframe and skin.

After completing all repairs, mechanics test the equipment to ensure that it works properly and record all maintenance completed on an aircraft.

Avionics technicians are specialists who repair and maintain a plane’s electronic instruments, such as radio communication devices and equipment, radar systems, and navigation aids. As the use of digital technology increases, more time is spent maintaining computer systems. The ability to repair and maintain many avionics and flight instrument systems is granted through the Airframe rating, but other licenses or certifications may be needed as well.

Designated airworthiness representatives (DARs) examine, inspect, and test aircraft for airworthiness. They issue airworthiness certificates, which aircraft must have to fly. There are two types of DARs: manufacturing DARs and maintenance DARs.

Inspection authorized (IA) mechanics are mechanics who have both Airframe and Powerplant certification and may perform inspections on aircraft and return them to service. IA mechanics are able to do a wider variety of maintenance activities and alterations than any other type of maintenance personnel. They can do comprehensive annual inspections or return aircraft to service after a major repair.

Repairmen certificate holders may or may not have the A&P certificate or other certificates. Repairmen certificates are issued by certified repair stations to aviation maintenance personnel, and the certificates allow them to do specific duties. Repairmen certificates are valid only while the mechanic works at the issuing repair center and are not transferable to other employers.

Work environment?

Aircraft and avionics equipment mechanics and technicians work in hangars, in repair stations, or on airfields. They must meet strict deadlines while following safety standards.

Most of these mechanics and technicians work near major airports. They may work outside on the airfield, or in climate-controlled shops and hangars. Civilian aircraft and avionics equipment mechanics and technicians employed by the U.S. Armed Forces work on military installations.

Injuries and Illnesses

Aircraft and avionics equipment mechanics and technicians often lift heavy objects, handle dangerous chemicals, or operate large power tools. They may work on scaffolds or ladders, and noise and vibrations are common, especially when engines are being tested. Workers must take precautions against injuries, such as wearing ear protection and brightly colored vests to ensure that they are seen when working around large aircraft.

Work Schedules

Aircraft and avionics equipment mechanics and technicians usually work full time on rotating 8-hour shifts. Overtime and weekend work are common.

Pay?

The median annual wage for aircraft mechanics and service technicians was $65,380 in May 2021. The median wage is the wage at which half the workers in an occupation earned more than that amount and half earned less. The lowest 10 percent earned less than $38,270, and the highest 10 percent earned more than $98,590.

The median annual wage for avionics technicians was $69,280 in May 2021. The lowest 10 percent earned less than $38,700, and the highest 10 percent earned more than $100,860.

Mechanics and technicians usually work full time on rotating 8-hour shifts. Overtime and weekend work are common.